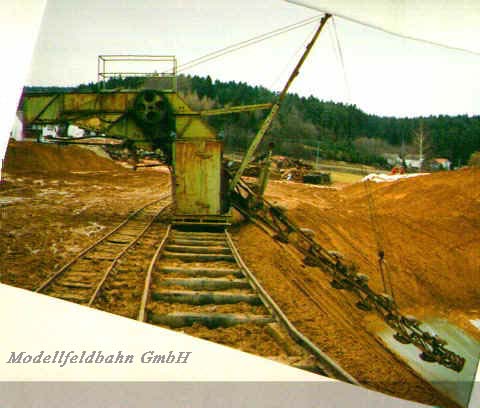

Modellfeldbahn GmbH i.G.

Bucket chain excavator of the company "Faller"

These bucket chain excavators had been built in the fifties and sixties of the last century by the company Faller in Ludwigshafen/Rhein in Germany.

The pictured bucket chain excavator of the type Faller is digging in low cut loess clay for the tile production of the „Gerhahersche“ roof tile company in Möding at Landau at the Isar in Bavaria, Germany.

Low cut means, the excavator takes the material from below of the excavator up into the skips.

The opposite is the high cut; here the excavator takes the material from above of the excavator down to fill the skips.

Unfortunately, the industrial narrow gauge railway of the „Gerhahersche Dachziegelei“ is already history and the bucket chain excavators (there were three) had been scrapped. This fate occurs to nearly every bucket chain excavator working with industrial railways.

Beside exploiting clay, this excavator can also be used to dig gravel, peat, for building drainage canals and for digging the covering earth to prepare for the open-cast working.

The advantage of the bucket chain excavator is the regular erosion-free digging (constantly with the digging angle, e.g. 45°). So there are no digging holes being filled with rain water soaking the surrounding area and bringing the slope to slip; because of the regularly digged outline, thereby the rain water always equally drains without staying in the slope.

Exploiting clay, the bucket chain excavator contributes to a substantial quality improvement of the clay. By equally scraping, it opens the clay and makes it thereby smoothier (the clay soaks better in water and can so be better kneaded and the clay better oxidizes).

The Prototype